Contact Us

Fax:+86-539-7811098

Tel:+86-539-7811111

E-mail:xyxmj@aliyun.com

Address: Junan Dadun Industrial Park, Linyi, Shandong, China

Sand tile

Category:

keywords:

- Product Description

-

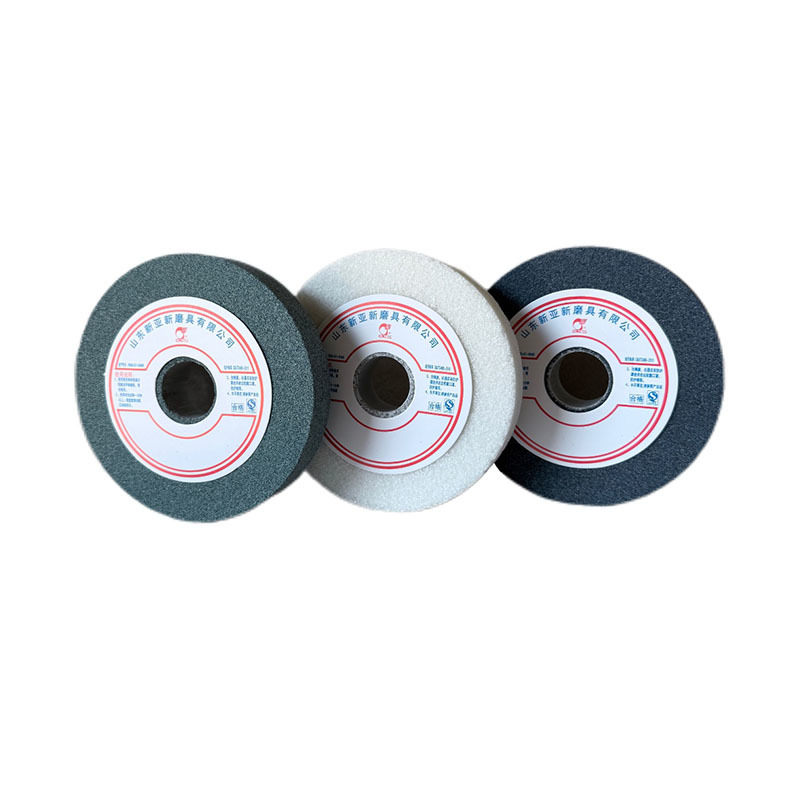

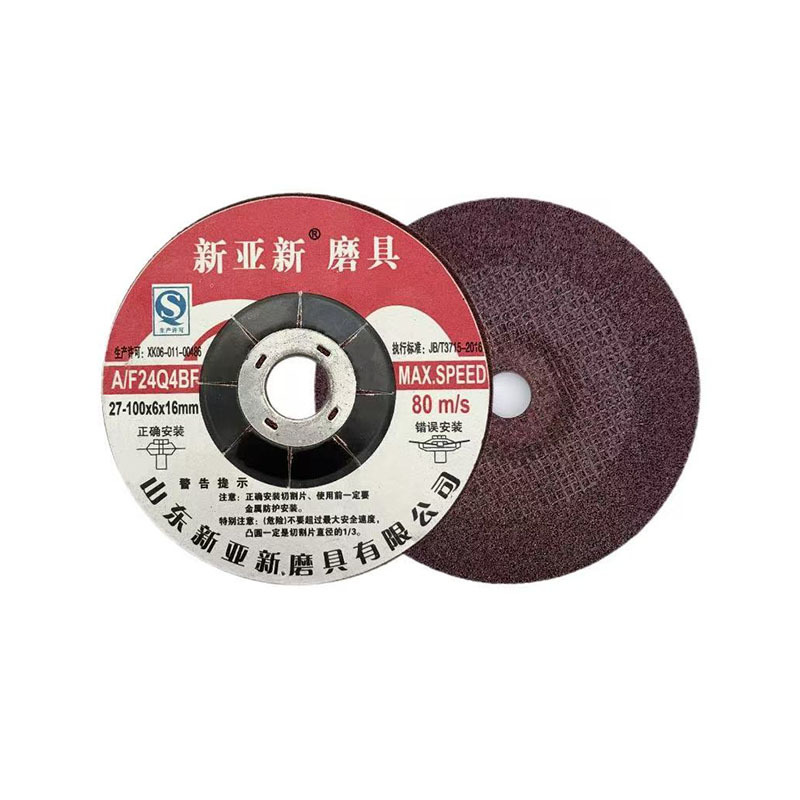

Grinding tools are used for grinding, polishing, and finishing. Most grinding tools are artificial grinding tools made of abrasives and binders; there are also natural grinding tools made directly from natural minerals. In addition to being widely used in mechanical manufacturing and other metal processing industries, grinding tools are also used in food processing, papermaking, and the processing of non-metallic materials such as ceramics, glass, stone, plastics, rubber, and wood.

Grinding tool structures are roughly divided into three categories: dense, medium, and loose. Each category can be further subdivided into several grades, distinguished by the structure number. The larger the grinding tool structure number, the smaller the volume percentage of abrasives in the grinding tool, and the wider the gap between the abrasive grains, indicating a looser structure. Conversely, the smaller the structure number, the tighter the structure. Grinding tools with a looser structure are less prone to dulling during use, generate less heat during grinding, and can reduce the heat deformation and burning of the workpiece. Grinding tools with a tighter structure have abrasive grains that are less likely to fall off, which helps maintain the geometric shape of the grinding tool.

During the use of grinding tools, when the abrasive grains become dull, due to the partial fragmentation of the abrasive grains themselves or the fracture of the binder, the abrasive grains partially or completely fall off the grinding tool, and new cutting edges constantly appear on the working surface of the grinding tool, or new sharp abrasive grains are constantly exposed, allowing the grinding tool to maintain its cutting performance for a certain period of time. This self-sharpening property of grinding tools is a prominent feature compared to general cutting tools.

According to their raw material sources, grinding tools are divided into two categories: natural grinding tools and artificial grinding tools. The only natural grinding tool commonly used in the mechanical industry is oilstone. Artificial grinding tools are classified according to their basic shape and structural characteristics into five categories: grinding wheels, grinding heads, oilstones, and abrasive bricks (the above are collectively referred to as bonded abrasives) and coated abrasives. In addition, abrasives are also customarily classified as a type of grinding tool.

Product Inquiry

Please fill in the information correctly to get a free quote!